|

Changzhou Dali Plastics Machinery Co.,Ltd.

|

Sheet Drain Production Line

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

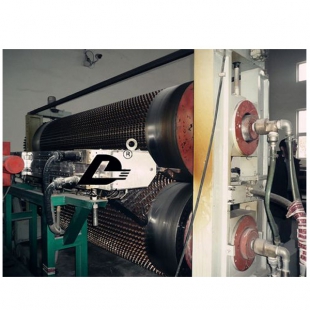

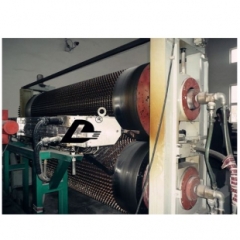

Vacuum forming-using vacuum pump and rollers with concave cups and convex studs, for producing sheet with uniform dimpled cores.

Vacuum forming-using vacuum pump and rollers with concave cups and convex studs,for producing sheet with uniform dimpled cores.

Calender roller pressing—using two rollers of concave cups and convex studs,pressing against the hot resin melt,forming uniform dimpled cores.

The dimpled structure of sheet drain can help to drain rain water quickly,dramatically reducing even virtually eliminate hydrostatic pressure imposed to water proof materials,which is a good method of active water proofing by draining out water directly.

Application:

Greening project–garage roof greening,roof garden,vertical planting,slop planting,football field,golf course;

Civil engineering-airport, road base, subway, tunnel, landfill;

Architecture—upper and lower part of construction base, inner and outer wall body,

flooring and roof of basement, house roof and heat insulation layer;

Water project—reservoir, water pond and artificial lake;

Traffic engineering– high way,railway base,dam and slope.

Specifications:

Drainage sheet product line;

Flat head die extrusion;

For water drainage in contruction;

CE certification

Customizable design;

Process:

Feeding systems with pneumatic or helix loaders;

Extruder with screen changer;

Flat Extrusion Die-heads;

Calender roller on which protrusions and pits are shaped;

Chill rolls where extruded melt is transforme d into a film and quickly cooled down;

In-line triming equipment;

Sheet guiding system;

Surface winding unit;

Edge trim recycling system;